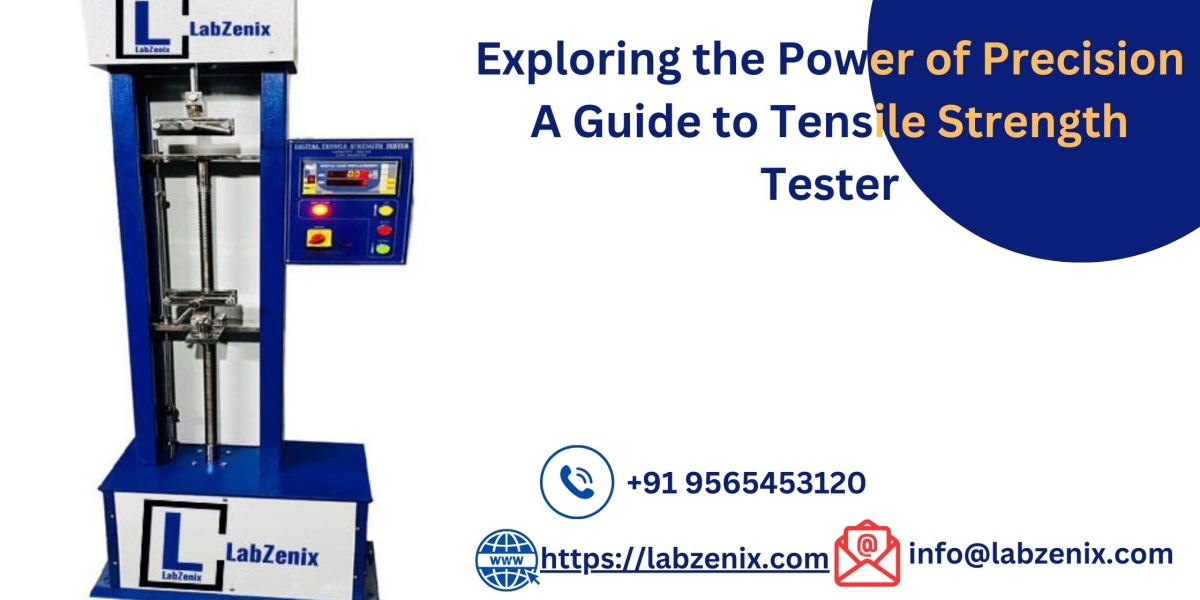

Tensile Strength Tester, manufacturers, engineers, and researchers can assess how materials such as metals, polymers, textiles, and composites respond when stretched or pulled. This test is key to guaranteeing that materials perform optimally and remain safe in various industries.

What Is Tensile Strength?

Tensile strength refers to the maximum load a material can withstand before breaking or undergoing permanent deformation when stretched. This property is critical in understanding how materials will behave under stress, ensuring their suitability for use in high-stress environments. It's an essential factor in materials like metals, fabrics, and construction components that need to meet exacting performance standards.

How Does a Tensile Strength Tester Work?

A Tensile Strength Tester works by gradually applying force to a material until it breaks or reaches a critical point of elongation. During testing, important measurements are taken:

- The maximum tensile strength (the highest stress the material can endure without failure).

- The elastic limit (the point beyond which the material will undergo permanent deformation).

- The elongation (the extent of material stretching before failure).

These readings help determine whether a material is fit for use in demanding applications.

Types of Tensile Strength Testing Equipment

Different types of tensile strength testers serve various testing needs. Here are some of the most commonly used:

Universal Testing Machines (UTMs): Flexible machines that are capable of conducting multiple types of tests, including tensile, compression, and flexure tests, to accommodate diverse applications.

Hydraulic Testers: Typically used in heavy-duty testing scenarios, hydraulic systems apply controlled force for testing high-capacity materials such as metal alloys and large structural components.

Portable Tensile Testers: Small, easy-to-use testers perfect for on-site evaluations, providing quick, reliable results without the need for extensive setup or equipment.

Electronic Tensile Testers: Equipped with advanced digital controls, these machines offer high precision and automation, ensuring accurate testing with minimal operator involvement.

Applications of Tensile Strength Testing

Tensile strength testing is indispensable in multiple sectors to assess materials' reliability and strength:

Research and Material Development: Materials scientists use tensile testing to evaluate and develop new materials, ensuring they meet strength and flexibility standards.

Manufacturing: Quality control in manufacturing depends on tensile testing to guarantee that products and raw materials will endure stress in use. It ensures that manufacturing standards are upheld.

Construction: In the construction industry, tensile strength testing ensures that construction materials, such as metals, cables, and concrete reinforcements, can withstand the pressures they'll encounter during use.

Aerospace and Automotive: Critical for aerospace and automotive industries, tensile testing ensures materials perform safely under extreme conditions and high levels of stress.

Consumer Products: From clothing to everyday plastic products, tensile strength testing ensures products will last during regular use and maintain their integrity.

Why Tensile Strength Testing is Essential

Tensile strength testing plays a crucial role in ensuring the reliability and safety of materials. The key benefits include:

- Enhanced Safety: By understanding material strength, industries can avoid dangerous product failures or accidents.

- Better Material Selection: Tensile testing helps engineers choose the appropriate material for specific applications, optimizing performance.

- Regulatory Compliance: Tensile strength tests are often required to meet industry standards, ensuring that products adhere to safety and quality regulations.

- Cost-Effectiveness: By preventing material failures before they happen, tensile testing reduces the need for costly repairs or product recalls.

- Improved Design: Testing data guides product designers in selecting more suitable materials, refining their designs for maximum strength and durability.

How to Choose the Right Tensile Strength Tester

When choosing a tensile strength tester, consider several factors:

- The material type to be tested (metal, rubber, plastic, etc.).

- The required force capacity needed to test your materials.

- The level of accuracy needed for your specific use case.

- Special features like real-time data logging and computer integration.

- Compliance with relevant industry standards such as ASTM or ISO.

At Labzenix, we offer a range of high-precision tensile strength testers designed to suit various testing applications. Our equipment is crafted to meet the demanding requirements of researchers, manufacturers, and quality control teams, ensuring accuracy and reliability.

Conclusion

Tensile strength testing price is indispensable in ensuring materials can perform under stress and meet safety standards. From research and development to quality control and consumer product testing, this process plays a vital role in guaranteeing durability, performance, and safety.

If you're seeking the best tensile strength testing equipment for your needs, visit Labzenix today at Labzenix. Our reliable solutions are designed to provide the most accurate and useful results, helping you optimize material selection and product design.